Developing the “Full Party” Mold Maker

By A Mystery Man Writer

Description

Cross Training, In-House Capabilities and Collaborative Design

3D Studies Track - BFA Art Undergraduate Program - Art and Design Department - Missouri State

How to Develop a New Electronic Hardware Prototype & Products for Your Company

Blow Molding - ScienceDirect

How to Develop a New Electronic Hardware Prototype & Products for Your Company

The American Mold Builder 2020 Issue 1 by petersonpublications - Issuu

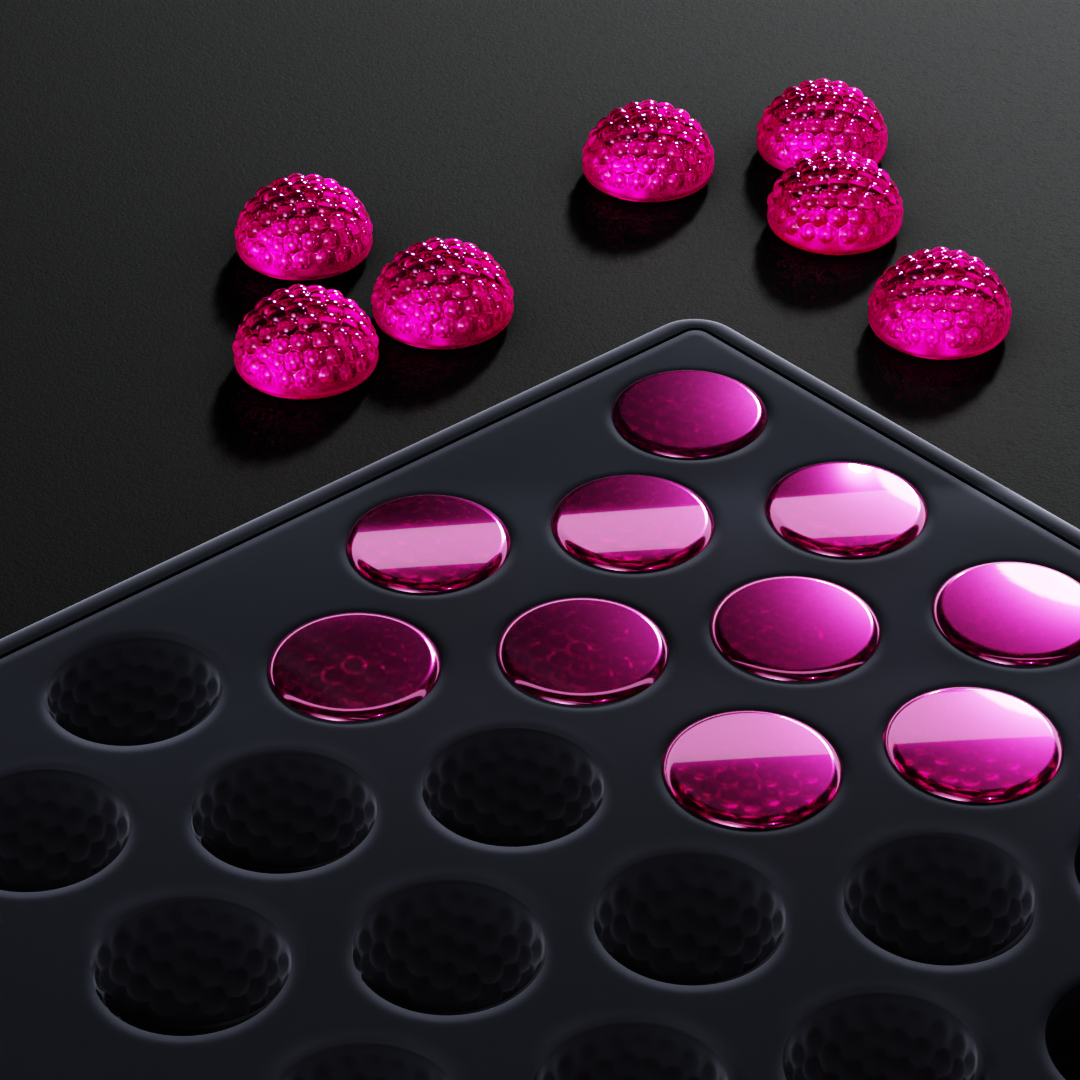

Mold Star silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star will

Mold Star 20T - 1A:1B Mix By Volume Translucent Platinum Silicone Rubber - Pint Unit

Create Custom Molds

Custom Manufacturing Injection Molding Moulds & Parts - UPMOLD

Developing the “Full Party” Mold Maker

Do manufacturers know how long it takes them to produce a product? - Quora

from

per adult (price varies by group size)